Agenda

Introduction

Hi Axapta People! Before we start the purchase business process, we must set up initial data in Axapta. In this training lesson, we will understand and set up the following:

- Vendor

- Warehouse structure

- Pallets and forklift

Let’s begin.

As you may remember the initial data from our previous trainings is the follows:

- Company purchases 5,000 items of Bottle Red 0,5 and 3,000 items of Cans Standard Black

- Company vendor is Big bottle company

We need more data for a full-fledged purchase process including the following (I suppose that you have already downloaded the demo data):

- Company warehouse structure

- Company pallet types

- Company forklift trucks

- Extend the Bottle and Can dimension to be able to track a pallet and location

Vendor

We may now create the Big Bottle vendor:

- Go to Accounts payable > Common Forms > Vendor Details. The Vendors form opens.

- Create a new record by pressing CTRL+N. Fill in the following fields:

- Vendor account = 1000

- Name = Big Bottle

- Group = 50

- Save the record. (If you encounter an error “Number sequence for the reference Address book ID in parameters in the Global address book module has not been set up”, do following.)

Now, we have set up the vendor. One field that we should discuss is the Group field. What is the Group field used for? In this training lesson, we have set up general ledger accounts for items. We have studied that a general ledger account contains information (in a money equivalent) about a concrete type of assets, liabilities, or shareholders’ equities. If a company needs to distinguish the item cost (asset) purchased from different groups of vendors, then a vendor group helps. This field relates to the Financial training scope. So I won’t explain it in details in this training. But, I will write short example that can help you understand what a vendor group is used for.

Company warehouse structure

A company’s warehouse physical structure contains the following entities:

- Sites. A site is a geographical location. A site includes one or several warehouses.

- Warehouses. A warehouse is a commercial building for storage of goods.

- Aisles. An aisle is a space for walking with rows of seats on either side or with rows of seats on one side and a wall on the other. In warehouses, rather than seats they have a rack to either side.

- Racks. A rack is a material handling storage aid system designed to store materials on pallets. One more rack example.

- Shelves. The rack system composed of shelves.

- Bins. A bin is a position on a shelf.

A company’s warehouse logical structure contains the following entities:

- Locations. It is a physical place in a warehouse that must be used as one entity. A location can be an entire aisle or a rack, a shelf or a bin. If, for example, a warehouse has aisles and racks only (without shelves and bins), a location is an entire rack.

- Store areas. Store areas group locations by dividing the warehouse into designated sections for inventory with similar characteristics. There are two types of store area, and every location is connected to one of the folowing areas

: Input area and Picking area. An Input area is used in connection with a place where items are stored when they are received as inventory. A Picking area is used to determine picking routes. - Store zones. Store zones are used for prioritizing the store areas for arriving items. The store zones are thus made up of store areas. We will understand the meaning of this entity later in this training lesson.

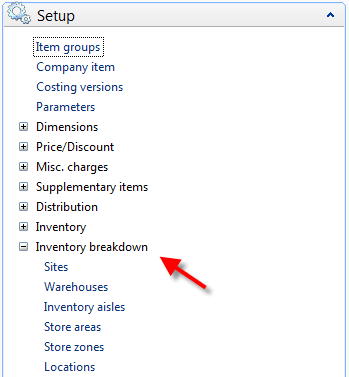

To set up a company warehouse structure (physical and logical), go to Inventory management > Setup > Inventory breakdown.

Inventory breakdown folder

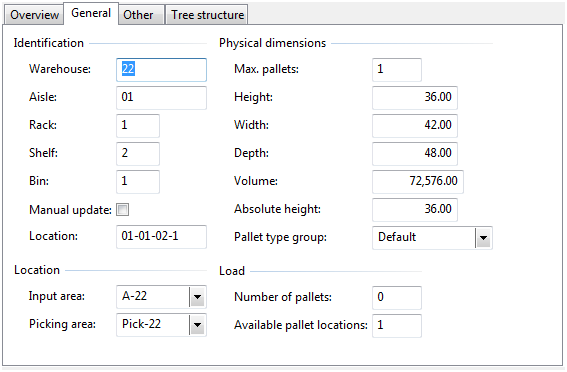

Under the Inventory breakdown folder, we can find the Sites, Warehouses, Inventory aisles, Store areas, Store zones and Locations forms. Note that a rack, a shelf, and a bin are not warehouse entities. We can’t create a rack, a shelf, or a bin and work with them (for example, associate to a location or inquire the on-hand for a shelf). In Microsoft Dynamics AX, Shelf, Rack, and Bin are properties of a Location. When a location is being created, the user chooses whether the location is rack, shelf, or bin. For example, in the following picture, a Location is a Bin that is situated in Bin 1, Shelf 2, Rack 1, Aisle 01 of Warehouse 22.

Location example

In our training, we will use warehouse 22. This warehouse contains seven aisles. Six aisles are used for storing goods and one aisle is used for receiving and issuing goods to and from warehouse. This one aisle is called Special. Each aisle (with the exception of Special) consists of 15 Racks with 3 Shelves each, each Shelf has one Bin. In this case, a Location is a Bin. A Location name consists of aisle, shelf, rack and bin IDs (names). The Special aisle doesn’t have any racks (or shelves and bins), this “aisle” contains five inbound and five outbound docks. An Inbound or an outbound dock is location. In this case, a Location is a part of an aisle. In our demo data, the location has the name (In_01 or Out_05). The EMPTY-P location is also a part of an aisle that will be used to store empty pallets.

Let’s find all these settings in Microsoft Dynamics AX. I have prepared several screen shots from our demo data.

To find this setting, take the following steps:

- To open the Warehouses form, go to Inventory management > Setup > Inventory breakdown > Warehouses.

- To view inventory aisles that belong to the current warehouse, click Inquiries > Inventory aisles in the Warehouses form.

- Each aisle (except the Special) contains racks, shelves, and bins. A Location in this case is a Bin.

- From the Inventory aisle form, click the Locations button.

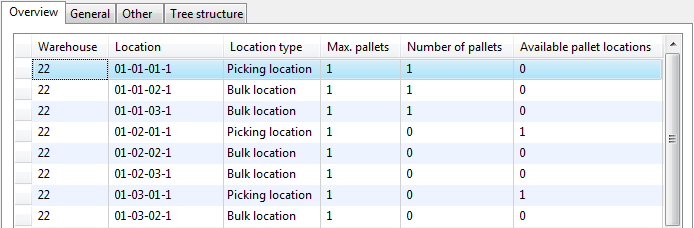

- The Locations form opens. This form shows locations that belong to the current aisle.

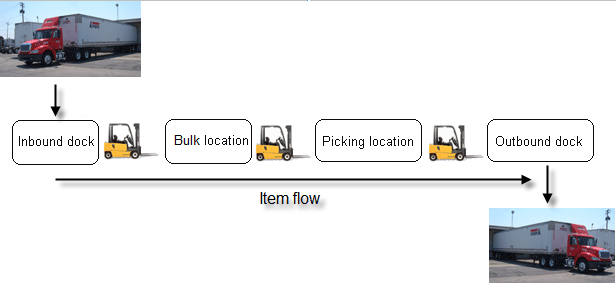

A Location can be of several types:

- Bulk location. Storage of received items. Identifies locations where items are stored until they are either moved to an outbound dock or used to fill a picking location.

- Picking location. Storage of items ready to picking (for sales process).

- Inbound dock. Location in the warehouse where items are received.

- Outbound dock. Location in the warehouse where shipments take place.

- Production input location. Location is used in the Production module.

The following picture helps understand what different location types are used for.

Location types

For example, in the Arrival journal (Inventory management > Journals > Item arrival > Item arrival), an item can arrive only to a location of the Inbound dock type.

A few words about a store zone and a store area. In Microsoft Dynamics AX, Warehouse Management store zones and areas are used for automatic placement of items into preferred locations. A store area groups locations. A store zone prioritizes store areas.

Let’s assume that the Bottle item arrives to the In_01 (inbound dock) location. Where must this item be stored? An item is associated with a store zone. This is done through the Warehouse item form.

Take the following steps to associate the Bottle item with a store zone:

- Go to Inventory management > Common Forms > Item details. The Item form opens.

- Find the Bottle item. Select the record and click Setup > Warehouse items. The Warehouse items form opens.

- For all Bottle item’s dimensions, we will use the same setup. We assume that the Bottle item arrives in warehouse 22.

- Create, a new record by pressing CTRL+N. Leave the item’s Dimension field empty and fill in the Warehouse field with the value 22.

- To assign a store zone, click the Locations tab.

- In the Store zone field, enter All-22.

- Save the record by pressing CTRL+S.

Set up the Can item with the same value.

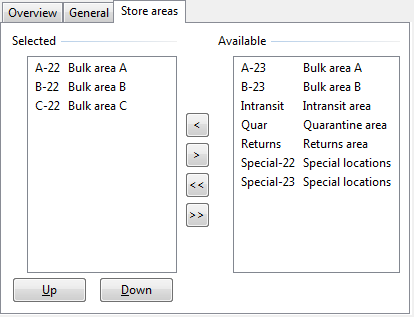

We have now set up the All-22 store zone for the Bottle item. Let’s find what store areas belong to this store zone and how store areas are prioritized.

- Go to Inventory management > Setup > Inventory breakdown > Store zones. The Store zone form opens.

- Find the All-22 store zone and click the Store areas tab. The following tab opens:

Store zone, Store areas tab

The information on this tab tells us that first, Microsoft Dynamics AX will try to put the Bottle item into a location from store area A-22. If there are no available locations, the location will be found in store area B-22. If there are no locations here also, the location will be found in store area C-22. If no appropriate location is found, an error message is shown: “Cannot find location for item Bottle at warehouse 22″.

To find what locations belong to store area A-22, take the following steps:

- Go to Inventory management > Setup > Inventory breakdown > Store areas. The Store area form opens.

- Find and select the record for the A-22 store area. Click the Locations button

- The Location form opens. This form tell us what locations are associated with the A-22 store area.

Locations form

Extend item dimensions

The Bottle and Can items have the following storage dimensions: Site and Warehouse. Since we want to track pallets and locations, we need to change the dimension group. What does it mean “to track locations” (or pallets)? It means that all inventory transactions (except those of the status Ordered) must be recorded with a location ID (pallet ID). With the help of this ID, we can inquire about how many Bottles are stored at a certain location or how many Bottles there are on pallet 555, for example.

To change the item dimension, perform the following steps:

- Go to Inventory management > Common Forms > Item details. The Item form opens.

- Find and select the Bottle item. Click the General tab and change the Dimension group field value from CS-W to CS-WLP. The CS-WLP dimension group has active Color, Size, Warehouse, Location, and Pallet dimensions.

Note: If you have at least one transaction with this item, Microsoft Dynamics AX will not allow changing the dimension group. If you want to delete all transactions in the current company, refer here for information.

Set up the Can item with the same value.

Inventory equipment

Now, we will set up pallet types and forklift trucks available in our company. This can be done under the following path: Inventory management > Setup > Inventory equipment.

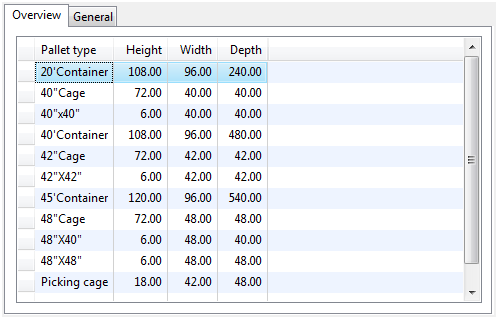

Since a pallet can have different height, width, and depth dimensions, we need to create different pallet types. I suppose that you use the demo data, so I only present a screen shot of the Pallet types form:

Pallet types form

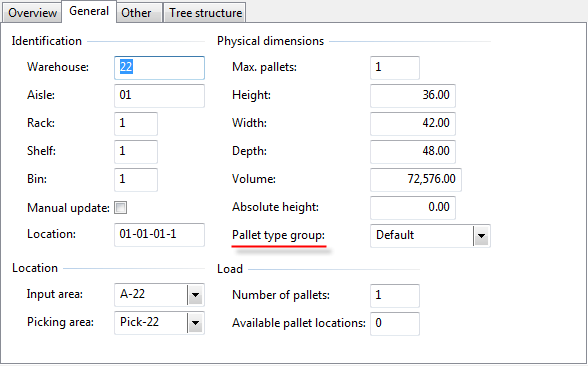

Now, we need to create pallet groups. Each location has a pallet type group parameter specified under the following path: Inventory Management > Setup > Inventory breakdown > Locations form.

Pallet type group on the Locations form

The Pallet group shows what pallet type can be stored at this location.

In my demo data, I have the following pallet groups:

- Default pallet type group contains pallet types:

- 40″x40″

- 42″X42″

- Large pallets pallet type group contains pallet types:

- 48″X40″

- 48″X48″

- Picking cages pallet type group contains pallet type Picking cage

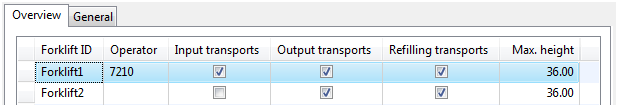

Let’s now set up a forklift truck. I assume that we will use only one forklift truck in our company warehouse. So, refer to the Forklift form’s screen shot for an example of forklift truck setup in Microsoft Dynamics AX:

Forklift form

OK, we have done a good work! We have set up all necessary data for the purchase business process (to be more specific, for its receiving part).

Summary

Today we have set up the initial data for the purchase business process, its receiving part.

Let’s review what we have done:

- Have created the Big Bottle vendor.

- Have understood and set up the company warehouse structure (warehouses, aisles, racks, shelves, bins, and locations).

- Have extended the Bottle and Can dimensions (have added Location and Pallet).

- Have understood and set up company warehouse equipment (pallet types, pallet groups, and forklift trucks).

In the next training, we will create a purchase order.

Very good material! Thanks for publishing that! Keep up the good work!

Excellent, very very good work!!! Highly appreciate, hope more release will be publish out.

Hi,

I have WMS I and not WMS II so things are a bit different. I would like to assign picking locations to items. I generated locations, but in the item details form –> Warehouse Items –> The default picking location is grayed out. How to enable it?

J.

Hi!

It is because your item doesn’t have the Location dimension. Go to the Inventory management > Common Forms > Item details > General tab > Dimension group field. Select dimension group with active Location dimension.

Hi,

It seems settings this does not have effect. I have run through the source code and came to next:

The inventDim.InventLocationId seems to be ” always. any idea?

J.

==

void setWMSLocationIdEnabled(InventDimGroupId inventDimGroupId)

{

NoYes locationActive;

InventDimSearch dimSearch = inventDimFormSetup.dimSearch();

;

dimSearch.find(inventDimGroupId, fieldnum(InventDim, wmsLocationId));

locationActive = dimSearch.dimActive();

if (!inventDim.InventLocationId)

locationActive = false;

inventItemLocation_ds.object(fieldnum(InventItemLocation, wmsPickingLocation)).allowEdit(locationActive);

inventItemLocation_ds.object(fieldnum(InventItemLocation, wmsLocationIdDefaultIssue)).allowEdit(locationActive);

inventItemLocation_ds.object(fieldnum(InventItemLocation, wmsLocationIdDefaultReceipt)).allowEdit(locationActive);

}

Hi. The code says:

1) The Location dimension must be active for the item

2) The Warehouse field must be filled in (in the Warehouse Items form).

😉

Thanks for for providing such a g8 stuff..!!! Good Work