Agenda

- Introduction

- Setting Up a Work Center

- Working Time

- Input Location

- Ledger Posting

- Default Parameters for Operation

- Summary

Introduction

In this training lesson, we will learn what a work center is and what its parameters are.

Machines, tools, people, and vendors that a company may use within a manufacturing process are defined as Work Centers which are created from within the Basic module.

The four types of a work center are:

- Machine

The most common type of work center, where one or more machines may be defined. - Tool

Tools that are used within a manufacturing process should be defined as this type. - Vendor

Define subcontractors to be of the type Vendor. - Human Resource

Any work carried out by people or teams must be defined for later attachment to a route operation.

Work Centers of a similar type or capability can be grouped together in order to form a pool of resource capacity. The system can use them when planning production. Each work center is related to a calendar which defines the availability of the resource throughout the working year. A work center which belongs to a group can inherit the properties of that group, thus saving time and effort in the setup and maintenance of the data.

Setting Up a Work Center

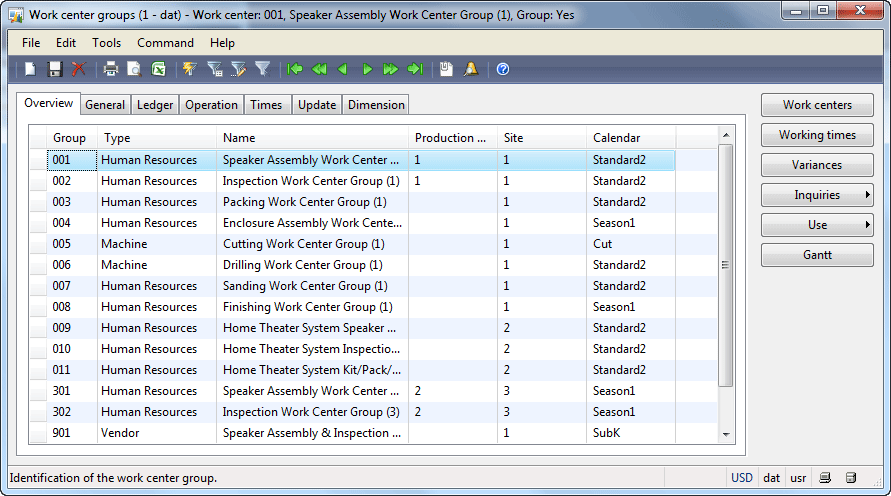

For setting up a work center, we will use this demo data (the same as for the Trade and Logistics training). To review work centers, go to Basic > Common Forms > Work center groups. The Work center groups form opens. Remember that in Microsoft Dynamics AX a work center can be created only inside a work center group.

A work center group can contain one or several work centers. Usually work centers that perform similar functions and are generally used interchangeably are combined in one work center group.

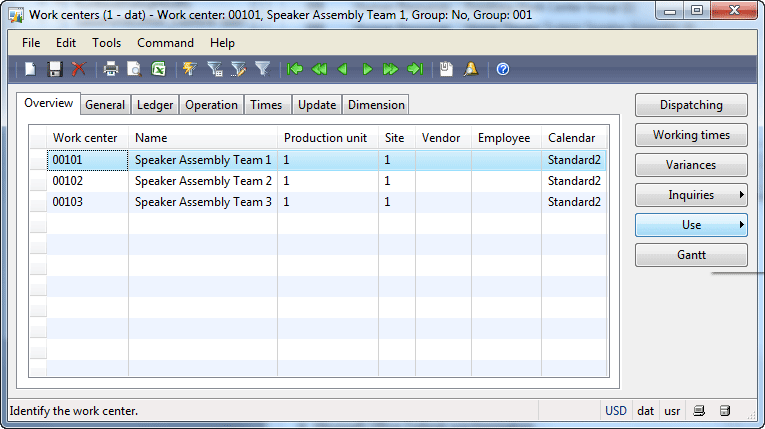

A work center group contains default parameters for a work center. If you click the Work centers button, you can make sure that the work center contains almost the same parameters and tabs.

Why does Microsoft Dynamics AX have work center groups? In the next training lesson, we will set up routes. A route determines the sequence of operations required for building a finished product. Each operation can be associated with a work center group. In this case, when a route is scheduled, an available work center (from the work center group) will perform the operation.

We will use the 011 work center group. This work center group contains the 01101 and 01102 work centers. To verify this, click the Work centers button.

Now, we will analyze a work center group parameters. Since a work center group and work center parameters are similar, we will only analyze the work center group parameters.

Working Time

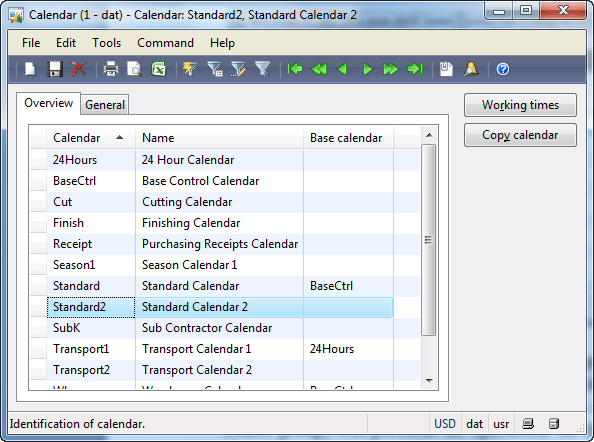

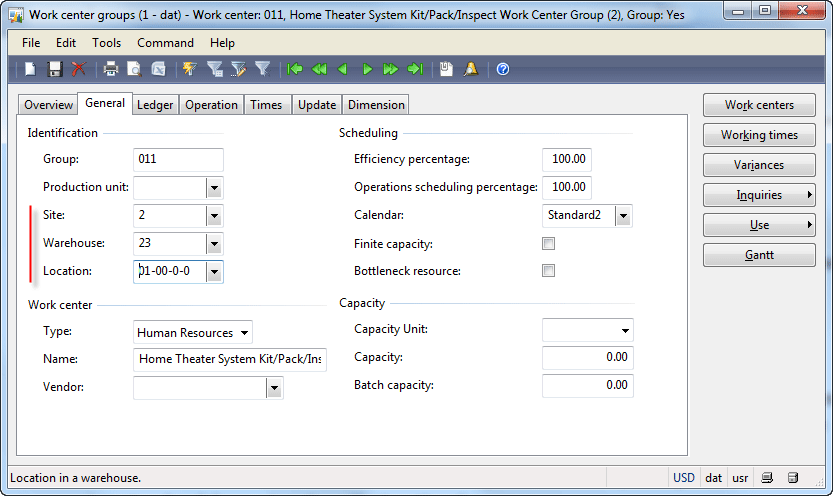

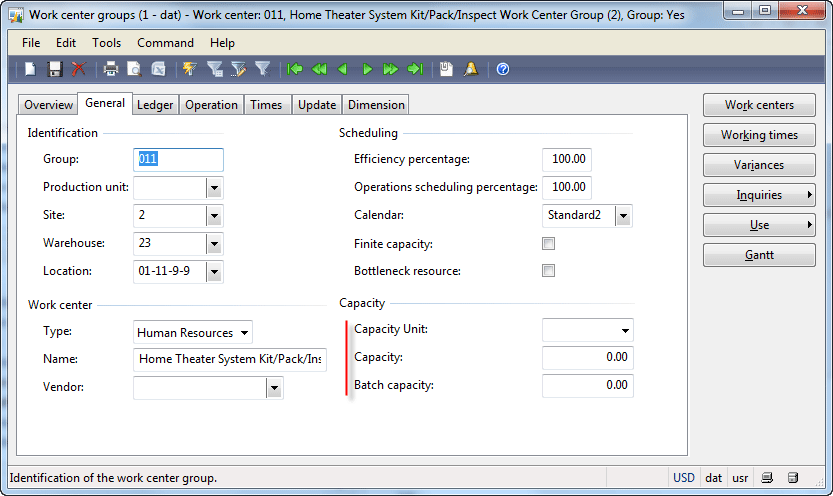

A work center is the company resource. All resources have limitations. Working time limit is defined with the help of a calendar. The default calendar used for the 011 work centers is Standard2. Let’s investigate the working time limit for the Standard2 calendar:

- Click Basic > Calendar. The Calendar form opens. Find the Standard2 calendar.

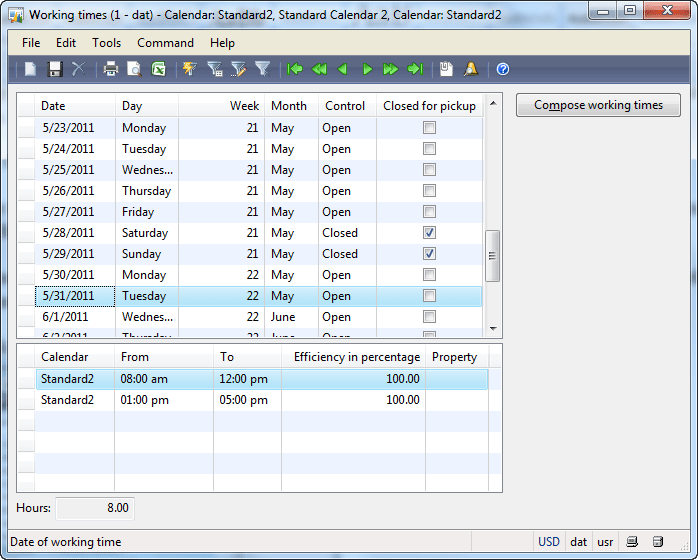

- Click the Working times button. The Working times form opens. This form contains the information about working days and times.

We can see that on May, 28 – 29 the calendar is closed (this is Saturday and Sunday), so work centers from the 011 work center group are not available on Saturday and Sunday. Also, we can see that during a day, work centers are available from 8 till 12 and from 13 till 17 (the lunch time is between 12 and 13). (The Closed for pickup check box is used for a warehouse (warehouse working time is also set up with the help of a calendar) and it means the item can’t be picked up from the warehouse on this day.)

For example, if the operation is running for 3 hours and is started at 4.00 p.m. on Friday, it will be finished at 10 a.m. on Monday. The start and end dates for operations are calculated during the production scheduling process.

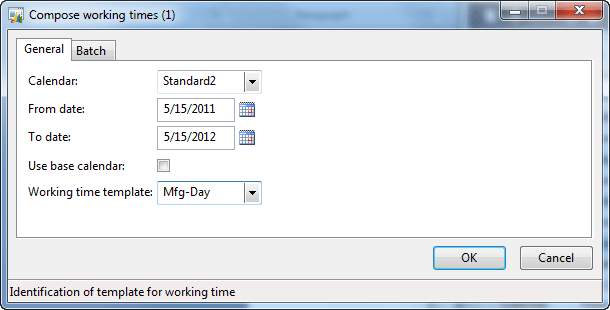

How is working time set up for the calendar? Of course, working time can be set up manually but for all days within a year it is very tedious. For this purposes the working time template exists. When a new calendar is created, the Working times form is empty. To create working times for the calendar, the user clicks the Compose working times button. In the Compose working times form, the user specifies the start and end dates and the working time template.

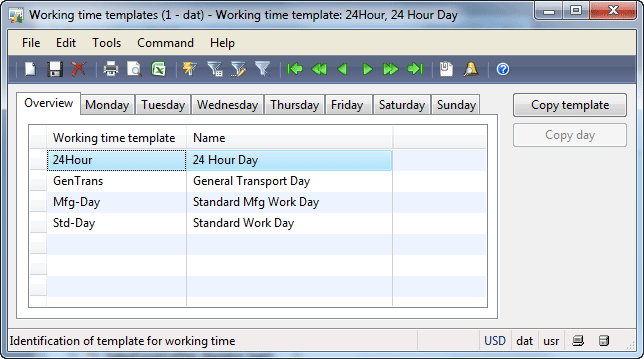

The working time templates are set up under Basic > Setup > Calendar > Workingtime templates.

In the Working time template form, the user can specify working time per day.

The 011 work center group has the following working time: from Monday to Friday, from 8 till 12 and from 13 till 17.

Input Location

One of the major work center parameters is the input location (especially if the Warehouse management is used). An input location defines the place in a warehouse where a work center is situated. This information is used when Microsoft Dynamics AX defines the place where BOM components are to be delivered. We will study the delivery process in the Production life cycle training lesson.

Let’s set up an input location for the 011 work center group:

- In the Work center group form, select the 011 work center group. Go to the General tab.

- Select 2 in the Site field, and the value 23 in the Warehouse field. Now, we want to specify the location. If we look up the Location field nothing is shown. That is because a work center can be assigned only for a production input location. But, the 23 warehouse doesn’t contain any production input location.

- To create a production input location in the warehouse 23, go to Inventory management > Setup > Inventory breakdown > Locations. The Locations form opens.

- Create a new record with the following values:

- Location type = Production input location

- Warehouse = 23

- Aisle = 01

- Max.pallets = 100

- Height = 360

- Now, we can set up a location for the Work center group.

Ledger Posting

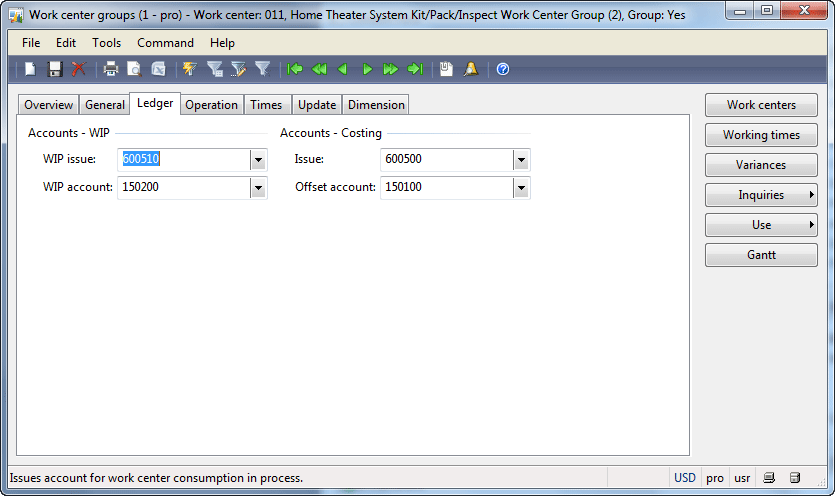

As you may already know, all company activities should be recorded to ledger accounts in a monetary equivalent. A work center is no exception. When a BOM item is processed, all expenses and the cost of work must be recorded to the general ledger. The Financial Manager sets up general ledger accounts that must be used for this purpose on Ledger tab of the Work center groups form.

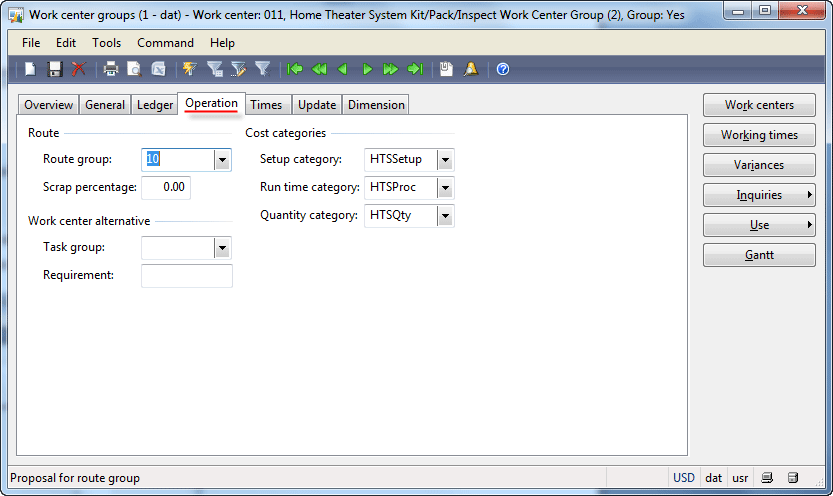

When a BOM item is processed, all expenses are recorded to the WIP issue account and the same amount of money (the cost of work for the processed BOM) is recorded to the WIP account (work in process). When the BOM production is finished, the previous accounts are reversed, the expense is recorded to the Issue account and the same amount of money (the cost of work for the produced BOM) to the Offset account. But the expenses and the cost of work can be recorded to the general ledger accounts from a costing group (the Work center groups form, Operation tab, Cost categories field group). It depends on the production order posting type. This type is set up when a production order is created – in the Create production order form, Setup field group, Ledger field. To use the ledger account from the work center, the Item+Work center value must be selected.

Financials is a very interesting part of the company routine. I started learning financials from this site. After the production module, I am planning to start the Financial module.

Default Parameters for Operation

Each work center is used to perform some operations for the BOM item. So, the work center group contains default parameters for the operation. In the next training lesson, we will study routes and operation in more detail.

Shortly, each operation consumes time from a work center it is assigned to. Capacity term relates to the operation. It shows the number of processed BOM items during specific time (usually per hour) for the operation in a specific work center. When a production order is scheduled, the time required for the operations is calculated and reserved.

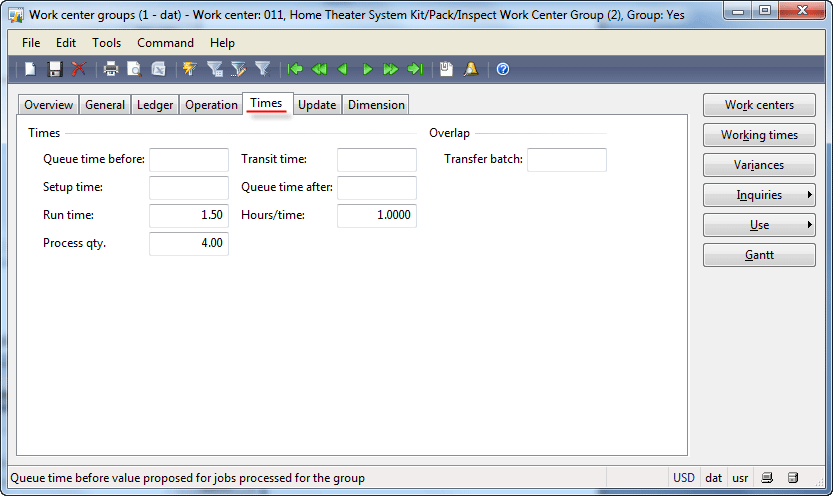

To set up default capacity parameters for the operation, go to the Times tab and fill in the Run time and Process quantity fields. For example, if during 1.5 hours only 4 chairs can be painted (painting is an operation), the Run time field must be filled with the 1.5 value and the Process quantity field with the 4 value. These values will be default for the “paint” operation in the current work center. Note that for all operations in the current work center, these values will be default.

This is the easiest way to set up default time required by an operation. In Microsoft Dynamics AX, the required time can be calculated in four different ways:

- Standard (as describe above)

- Capacity

- Batch

- Work center batch

The calculation formula is set up at the operation level (we will see this in the training lesson). By default, the Standard method is used.

Other default fields for operation that are used during the calculation of the required time are:

- Capacity unit

- Capacity

- Batch capacity

They are placed on the General tab, in the Capacity field group:

Other default fields for the operation are placed on the Operation tabs.

We will discuss these fields in the Routes and Operations training lesson.

Summary

In this training lesson, we have studied the Work centers. As you may have noticed, the parameters that relate to work center set up are not so numerous. A lot of work center parameters are the default parameters for operations.

The major work center parameters are a work center type, an input location, a calendar, and ledger accounts. Other work center parameters are: production unit, efficiency percentage, operation scheduling percentage, finite capacity, bottleneck resource, and vendor name. All other parameters are default parameters for operations.

Over?

Anxious for good training!

This is it? I was really hoping for something more.

Your efforts are really appreciated. You do not know how many thousands of resources become “better” in their Ax acumen.Please don’t leave it in the mid way.

hi gr8 information,

i doesnt got from any where