Agenda

- Introduction

- Setting Up Materials Required for Product Creation

- Setting Up Resources Required for the Product Creation

- Accounting materials and resources required for production of a product

- Summary

Introduction

Hi! Today we will learn what the Production module is used for and understand the basic building blocks of production.

Why does the company need to have the Production module? …The answer is for managing and accounting the Production. What is Production? Production is a process of creating products. And, what is a product?

“The noun product is defined as a “thing produced by labor or effort” or the “result of an act or a process”, and stems from the verb produce, from the Latin prōdūce(re) ‘(to) lead or bring forth’.”

So the Production module is used for the following purposes:

- Setting up materials (product structure) and resources (operations) required for a product creation.

- Accounting the product production process (accounting materials and resources required for producing a product).

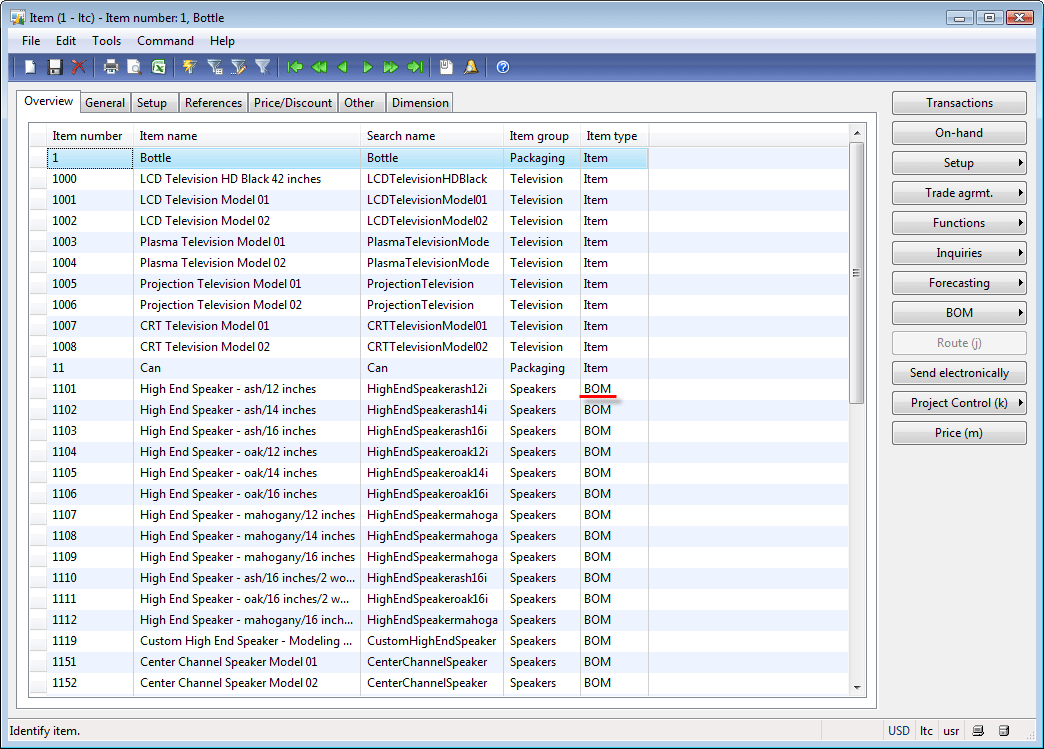

In Microsoft Dynamics AX 2009, a product is an item of the BOM item type (BOM – Bill of materials). Go to Inventory management > Common Forms > Item details.

Setting Up Materials Required for Product Creation (Product Structure)

Product structure contains the information about the materials that are required for building the product.

Item of the BOM item type (product) must be associated with the Bills of Materials.

“The bill of materials (BOM) is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, components, parts and the quantities of each needed to manufacture an end product”.

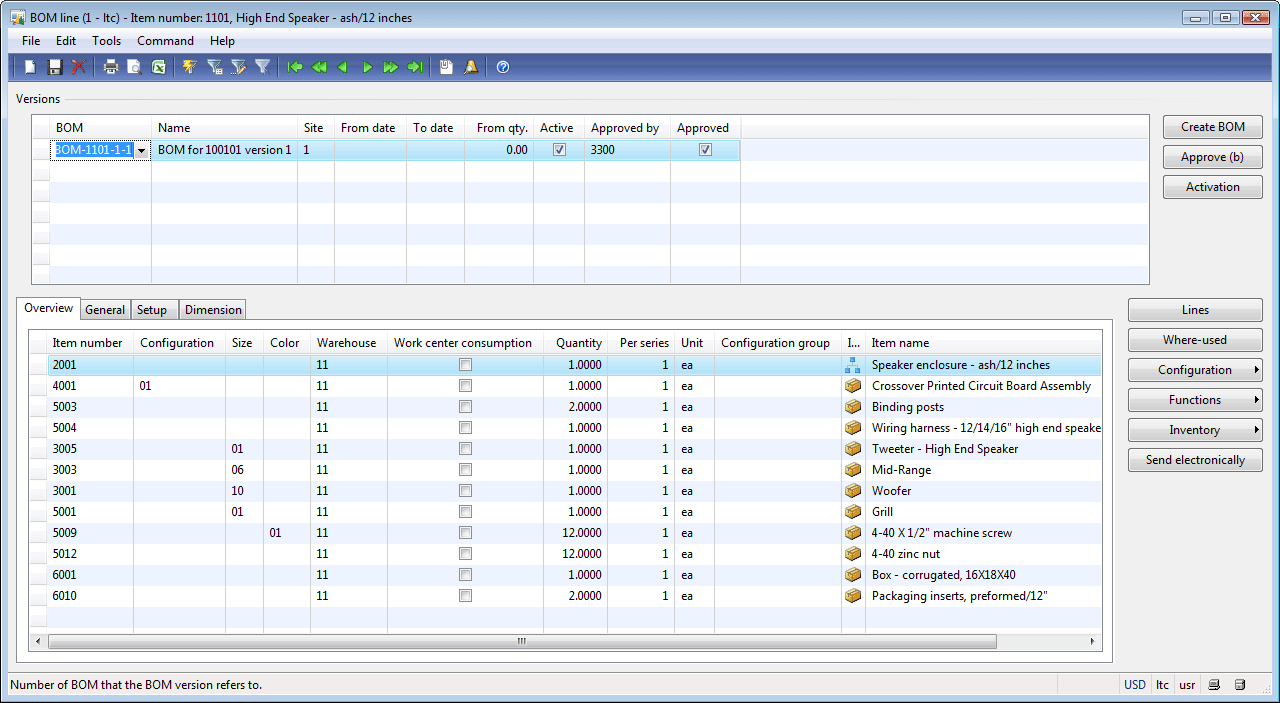

To view the BOM associated with the item, in the Item form, select necessary item and click the BOM > Lines menu button.

In our demo data, the 1101 item is associated with the BOM-1101-1-1 BOM. In the BOM line form, we can see the components that are used in order to produce the 1101 item.

Setting Up Resources Required for the Product Creation (Operations)

An operation contains information about the resources that are required for building the product.

An item of the BOM item type must be associated with the Route. A Route defines operations and their sequence required for producing the product. The operation contains information about the working time and the required resources. So, we can say that:

- BOM contains information about the materials required for building the product.

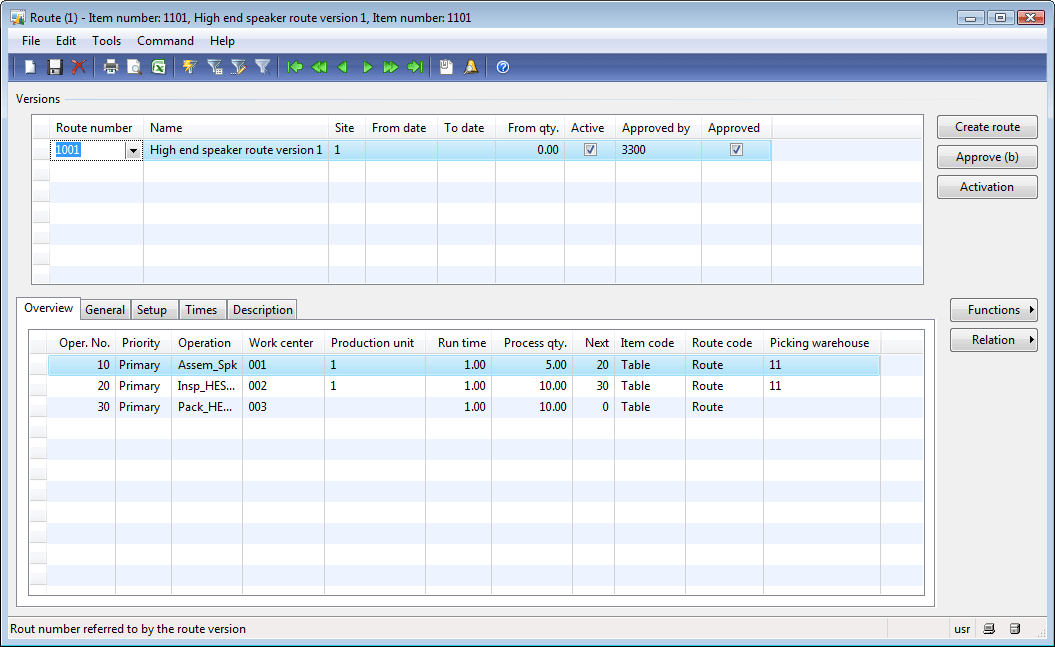

- Route contains information about the working time and the resources required for building the product.

Resources are presented in Microsoft Dynamics AX as work centers. In Microsoft Dynamics AX 2009, a work center can be of the following types:

- Machine

- Tool

- Human

- Operator

- Vendor

To view the Route associated with the item, click the Route button in the Item form.

In our demo data, the 1101 item is associated with the 1001 Route. In the Route form, we can see the operations (work centers, working time) that are used for producing the 1101 item. We will learn how to understand the information presented in the Route form in the next lesson.

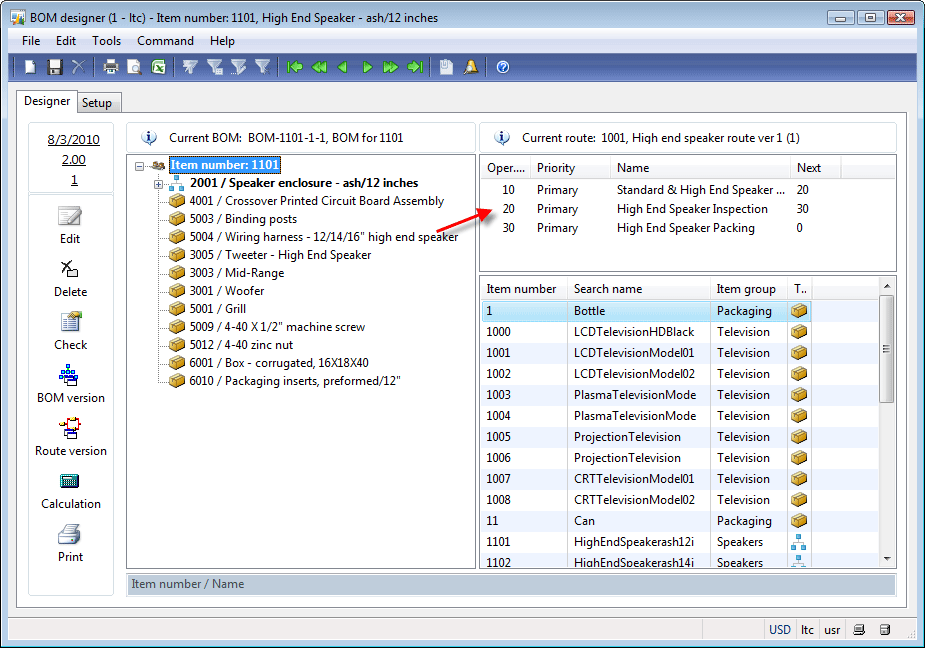

How are the operations and the materials connected?

Each material is manually associated with a specific operation.

- In the Item form, click the BOM > BOM lines menu button.

- Go to the General tab and enter the necessary operation in the Oper. No. field.

With the help of the BOM designer, do the following:

- In the Item form, click the BOM > Designer menu item.

- Drag and drop product materials to a specific operation.

Accounting materials and resources required for production of a product

A production order is used for managing the product creation process. It can be created from a sales order.

The production order follows a sequential “production life cycle”. The life cycle reflects the actual steps that are taken to manufacture an item. It begins with the creation of a production order and ends with a finished, manufactured item that is ready for the customer. Each step in the life cycle requires different kinds of information.

When the production order is ended, items that will be consumed are deducted from the inventory, the created product is added to the inventory and the costs of materials and resources are recorded to the general ledger accounts.

We will study the production order life cycle in detail later in the future lesson.

Summary

In this training lesson we have studied:

- Production module is use for:

- Setting up materials (product structure) and resources (operations) required for creating a product

- Accounting product production process (accounting materials and resources required for producing a product)

- Product is an Item of the BOM item type.

- Product is associated with a BOM and a Route.

- Bills of Material – BOMS

A Bill of Material or a BOM defines the recipe for making a product. Think of it as a list of ingredients which includes all the sub-assemblies, components, and raw materials required for making a single finished product. - Routes and Operations

A production route defines the process which is used for making a finished product. Sequential steps, or operations, are created which describe the Work Centres involved in the production process and how much time it takes to carry out each operation. - Work Centres

Work Centres represent production resources available to a company for making products. In Microsoft Dynamics AX 2009, a Work Centre can be a Machine, a Tool, a Human Operator, or a Vendor.

- Bills of Material – BOMS

- A Production order is used for managing the product creation process.

In the next training lesson, we will create and set up a new product.

very useful concepts

Such an interesting little blog, so glad I found it. I will tell my friends about this one & come back soon.

Thanks for information, it has clear Info here

I am x 2012 and need some training like this can you let me know where I can find something like this? This is great by the way but I am not on 2009. Thanks Jenn

HiFriend,

Thanks for sharing information regarding axapta. if you don’t mine do you have any ax2012 functional spec in this manner .I need Production and T & L.if you have can you please reply to above mail id.perticularly ineed more into

inventory.

Thanks

Harish…

Good explanation.